Colorado River water enters the CAP system near Lake Havasu, and from the moment it begins the 336-mile journey, it is skillfully managed from CAP’s Control Center. One way that is possible is through effective utilization of check structures.

The system’s 39 check structures act as a metering device, controlling the flow of water into and out of a segment, or pool, of the canal. Each check structure contains two radial gates that operate independently, a feature designed to provide system redundancy. The gates are operated by electric variable speed motors that Control Center Dispatchers can move in increments as small as 1/100 of a foot. The max capacity is 3,000 cubic feet per second.

“The exact height of each gate is based on what we are trying to achieve at that moment and is a delicate balance between system demand, maintenance activities, diversion targets, power market and other constraints,” said Control Center Supervisor John Hussen. “Our ultimate goal is to achieve the most efficient operational plan every day.”

The check structures’ geographical locations are based on the locations of pumping plants and riverbeds; some are as far apart as 10 miles; one is less than a mile from a pumping plant. They work together with all the other system features to ensure reliable water deliveries.

Comprueba 1, 2, 3

El agua del río Colorado ingresa al sistema CAP cerca del lago Havasu. Desde el momento en que comienza su viaje de 336 millas, se gestiona hábilmente desde el Centro de Control de CAP. Una forma de hacerlo es mediante el uso eficaz de presas de detención.

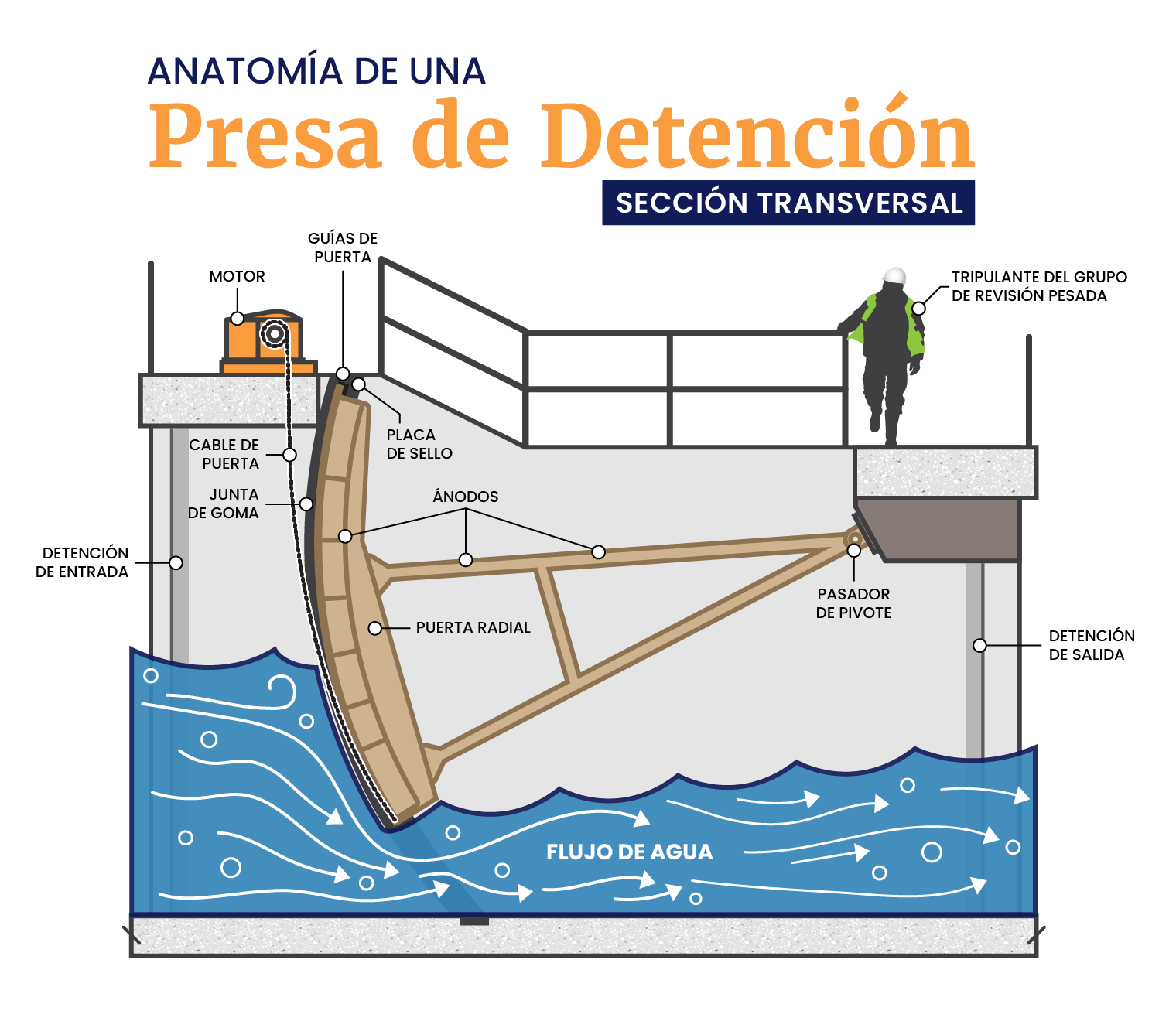

Las 39 presas de detención del sistema CAP funcionan como un dispositivo de medición, controlando el agua que entra y sale de un segmento o piscina del canal. Cada presa de detención tiene dos compuertas radiales que funcionan de forma independiente, una característica diseñada para proporcionar redundancia al sistema. Estas compuertas son operadas por motores eléctricos de velocidad variable que los despachadores del centro de control pueden mover en incrementos tan pequeños como 1/100 de pie. La capacidad máxima es de 3000 pies cúbicos por segundo.

“La altura exacta de cada puerta se base en lo que estamos tratando de lograr en el momento y es un delicado equilibrio entre la demanda del sistema, las actividades de mantenimiento, los objetivos de desvío, el mercado de energía y otras limitaciones”, dijo el supervisor del centro de control, John Hussen. “Nuestro objetivo final es lograr el plan operativo más eficiente todos los días”.

La ubicación geográfica de las presas de detención se base en la ubicación de las plantas de bombeo y los lechos de los ríos. Algunos están a una distancia de hasta 10 millas; uno está a menos de una milla de una planta de bombeo. Trabajan junto con todas las otras características del sistema para garantizar un suministro de agua confiable.