It’s been said that necessity is the mother of invention and that is definitely true in the case of access stoplogs, nicknamed “bubble logs.”

When the Bureau of Reclamation constructed the CAP system, including the cast-in-place concrete siphons that convey water under features such as roads and rivers, they assumed the siphons would be maintenance-free and thus, didn’t initially include a way to effectively dewater these siphons for inspections or repairs. That assumption proved to be incorrect.

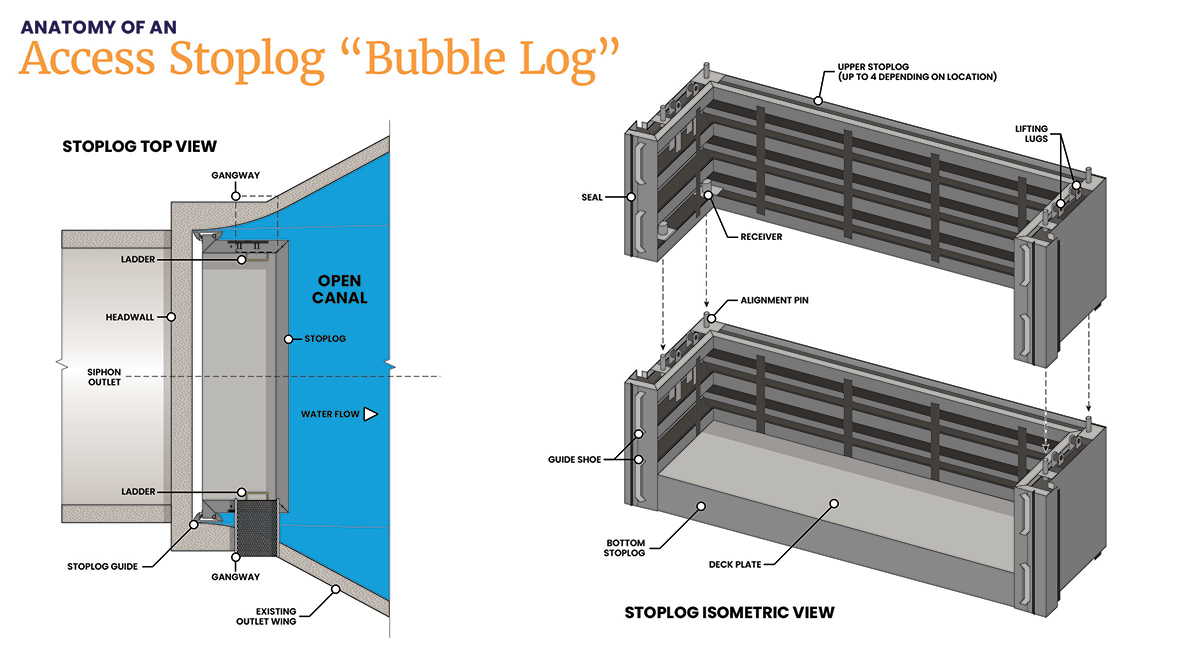

The most obvious solution would be to use stoplogs or “logs.” In earlier irrigation times, tree logs would be vertical stacked to create a water-tight wall to control water flow. That term carried over to modern times except that instead of actual logs, metal wall sections or bulkheads slide into stoplog guides and stacked vertically to stop water and create dry work area.

None of the siphons had stoplog guides. However, in three cases, Centennial Wash, Agua Fria River, and Salt River siphon, repair or replacement of the siphons was required, providing an opportunity to have stoplog guides retrofitted so stoplogs could be used for inspections or repairs.

That left four siphons that needed attention and, although the need to inspect a siphon is not frequent, it is still necessary and has to be done within narrow timeframes to minimize impacts to water users.

Initially, they tried to use the same style of stop logs CAP uses at check structures, which would stop water by completely blocking one end of the siphon. It was effective, but it was not efficient, and it didn’t provide enough space to install ventilation and pumps at the outlet end. Siphons can be more than a mile long and blocking the outlet may only leave one way in or out. In the event of an incident, returning to the entry point can be time consuming, especially if the injury is serious and time is of the essence.

Senior Mechanical Engineer Jason Foster said in the late 1990s, his predecessor got to work and created a new design: The original bubble log. This custom-designed stop log had semi-circle popouts on the face of the stop log that allowed access and gave them the “bubble log” nickname.

“The original bubble log design worked, but left room for improvement,” said Foster. “The access point was small and after you went in, you had to scoot under the frame, disconnect your harness, scoot again and then reconnect.”

It also wasn’t ideal for a stokes basket that is used to evacuate an injured person.

The team went back to the engineering drawing board and designed a new version — a modular system of stop logs that stack on top of each other like Legos. This design features a large access point that is easy and safe for workers and will accommodate a stokes basket for emergencies.

They made it look easy, but the engineering behind it was challenging.

“When designing these, we didn’t just consider functionality, we also had size and weight to think about,” said Foster. “We had to make sure the crane could handle the weight and that the access logs weren’t an oversized load so we could transport them to the site.”

Another design consideration was to account for the fact these stoplogs will float when the siphon is dewatered.

“After I realized these would float, I had the consultant extend the guides above the sidewall and add hold downs to account for the buoyant force of the water the stoplogs displace on the wet side,” said Foster.

He then worked with crane operators to design a lifting device that would both deploy and retrieve the stop logs underwater.

Now, Gila River, Cunningham Wash, Waddell, and Santa Cruz River Siphons have their own set of access stoplogs ready to be installed for inspections or repairs. And, although “bubble log” is no longer an accurate description of this access stoplog, the name has stuck.