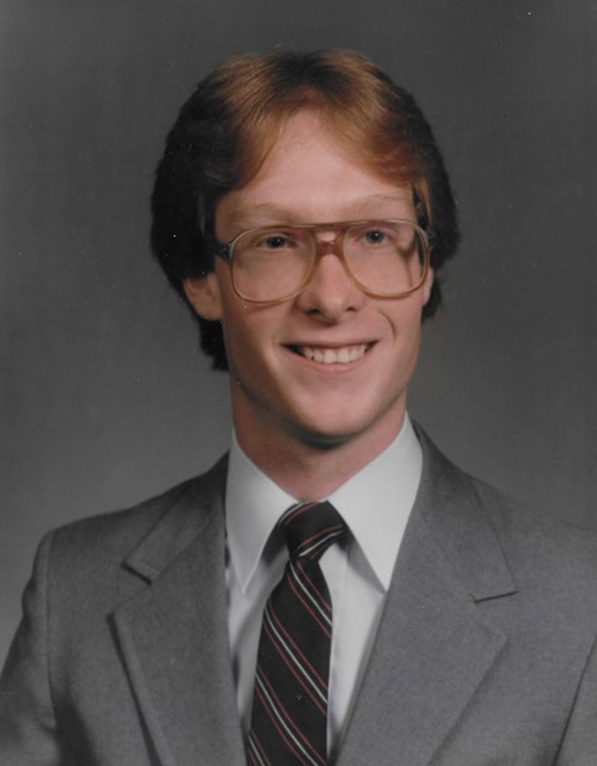

Phil Rettinger joined CAP in 2009 as a maintenance engineer, bringing nearly 15 years’ steel mill experience in engineering, maintenance and reliability. He currently is the director of Centralized Maintenance and Reliability.

Indiana native Phil Rettinger didn’t plan to leave his home state. The youngest of five was born in Valparaiso and for the first 39 years of his life, he never thought he would leave. He was surrounded by all things traditionally Midwest – industry, farming, sports and friendly neighbors – and he embraced it.

“There are lots of small towns dotted with farm fields, and I am one generation off the farm,” said Rettinger. “As a kid, I spent my time outdoors running through the woods with my brothers, shooting whatever popped its head up with our BB guns, instilling my love of outdoors, hunting and fishing.”

After graduating high school, Rettinger was at a crossroads. College didn’t seem financially feasible, so he got a job in the construction field framing houses. A few years later, his older brother started taking night classes at Purdue University’s extension campus and Rettinger, who had been saving his money, seized the opportunity. He juggled work and college and in 1995 successfully graduated with a degree in mechanical engineering.

Rettinger lived in a steel-producing region with steel mills all along the Lake Michigan shore, so he didn’t have to look far for his first job. Bethlehem Steel had a rich history of steel production and shipbuilding that had dwindled down to a core group of steel mills, one of which was located near his hometown.

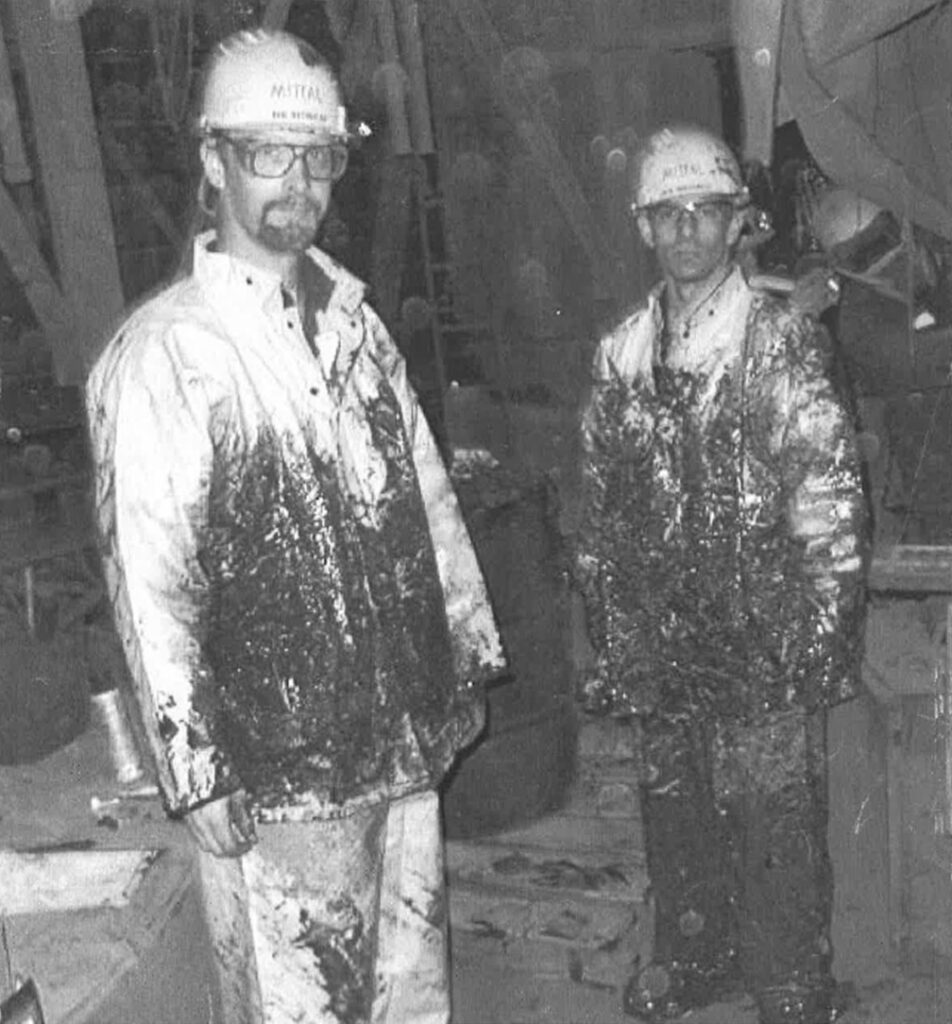

The mill was large – 7,000 employees – and his first opportunity was in the Steelmaking Department where molten iron was turned into steel and cast into slabs that would go to other departments to be rolled into plate or sheet. His mentor Ray, who had come to this plant after the mill’s closure in Johnstown, Penn., was a maintenance turn foreman – the one responsible for overseeing and supervising the maintenance work. Ray had 40 years’ experience and a no-nonsense attitude.

“He looked at me and said, ‘I am not dragging another snot-nose engineer around,’” said Rettinger. “Well, welcome to Bethlehem Steel. It was clear this was a place unlike anywhere I had worked – dirty, stinky and dangerous. And then there were the people who I could only nicely describe as ‘unique.’”

Fortunately, Rettinger saw an opportunity. He asked a lot of questions and learned a lot from Ray … and the relationship grew. And, although it was nearing the end of the 20th century, the department was in a time warp, stuck in the 1930s regarding labor relations, with lots of fighting and dysfunction. But Rettinger kept at it. He was hired into a position that was supposed to loop through different departments within the mill, but he spent all his time in mechanical maintenance. Not the opportunity he expected, but he embraced it.

“You had to toughen up quickly and learn how to adapt to the steel mill culture or you were in trouble,” said Rettinger. “And so began my professional career in maintenance and reliability.”

He worked in supervision and engineering roles in the mill, from maintenance turn foreman to mechanical area foreman, before landing as a maintenance engineer. The steel industry is cyclical, so change became normal – but it always came with opportunities. There were boom and bust periods. Bankruptcy, buyouts, and mergers were frequent. In nearly 15 years, Rettinger worked for four companies at the same location: Bethlehem Steel, International Steel Group, Mittal Steel and Arcelor-Mittal Steel.

He watched his friends and family go through transitions where they lost their pension, benefits and pay, and experienced reductions in force where nearly half of the company was let go. But the work stayed.

“I spent many a 16-hour shift in that plant trying to keep things going,” said Rettinger. “It was really difficult, but those times taught me valuable lessons about resiliency, negotiation, teamwork and psychology. Perhaps most significant was developing my passion for understanding and solving reliability problems on equipment.”

Not surprisingly, a man can only take so much. In 2009, deep in the downturn of the Great Recession, Rettinger was placed in charge of what he affectionately called “Operation Mothball.”

“I was working to ensure that if the plant shut down in the middle of the winter, the machines wouldn’t freeze up,” said Rettinger. “Well, that sounded like I better start looking for a new job. At that time, I had enough and thought there had to be something better than this place.”

So, he started looking, and he found it – Central Arizona Project. He read the job description and recognized that it described similar work to what he was doing – with different equipment – so he applied. He’d been to Arizona once on a motorcycle trip and loved it. But there were so many questions. Will the house sell and how quickly? Will his wife and kids like it in Arizona? What does a “dry” heat mean? What’s a Gila monster, and how big are they?

Before long, Rettinger was hired as a CAP maintenance engineer and headed to Arizona to find answers to all those questions. What he found was a position where he was empowered to make decisions and was responsible for his own actions. He was in a culture that exposed him to a new way of doing maintenance and reliability in an environment where he could make the right choices instead of just surviving. Best of all, he found a company where he felt supported and appreciated.

“People were supportive, and I found folks who once again believed in me and were willing to take a chance,” said Rettinger.

In 2012, he became the manager of Maintenance West and after eight years was promoted into the role as the director of Field Maintenance before taking the helm as the director of Centralized Maintenance and Reliability.

His engineering background is evident in his work style, which is driven by data and analytics, processes and planning. He’s been part of CAP’s efforts to improve reliability of the system, evident in the most recent award that was presented to CAP, the Uptime Award for Best Work Execution Management Program. His team includes a spectrum of professionals: maintenance workers, electricians, millwright mechanics, reliability engineers, shop mechanics, maintenance planners and information technology administrators. And their experience runs the gamut from apprentices beginning their education to seasoned journeymen nearing the end of their career.

As Rettinger looks back on his path and decision to leave his home state, he has no regrets.

“Looking back on things, I realize that coming to CAP was the best thing that ever happened to me,” said Rettinger. “I know most CAP employees feel the same way, but if I ever need a reminder, the steel mill is hiring.”

KRA: Workforce

Being a premier employer that attracts and retains an exceptional and diverse workforce