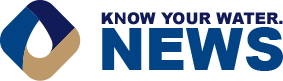

CAP Water Control Dispatcher Miguel Ayala steps in front of an array of screens and graphs and checks a log of day-ahead water delivery orders. The overnight monsoon thunderstorms had given way to a morning of dark, overcast skies.

Inside the CAP Control Center that remotely operates the entire 336-mile system, the operations team was adjusting.

“Rain is fantastic,” Ayala said. “But for real-time operations on this system, it means changes.”

Reacting to rain

Overnight rain had drenched certain areas in central and southern Arizona. So some water users called the Control Center to significantly reduce the amount of water they wanted delivered from what they had ordered for delivery the previous day.

No problem. Ayala could do that from the Control Center.

He clicked a few buttons, and far from headquarters, “invisible hands” stopped a few of the 109 pumps out of 15 total pumping plants that lift water uphill across the course of the CAP system. To control water flow, he also raised or lowered radial gates at the specific turnouts based on each customer’s request.

Adjustments were made, and deliveries stayed on schedule.

All the system features – check gates, pumping plants and turnouts – are operated remotely from this room that resembles the cockpit of Star Trek’s “Star Ship Enterprise” (minus a windshield). On two decks, multiple workstations with large monitors stacked together glitter with graphs and data. From here, the Supervisory Control and Data Acquisition (SCADA) system (a software program) monitors 30,000 data points along the system and relays information back to the Control Center.

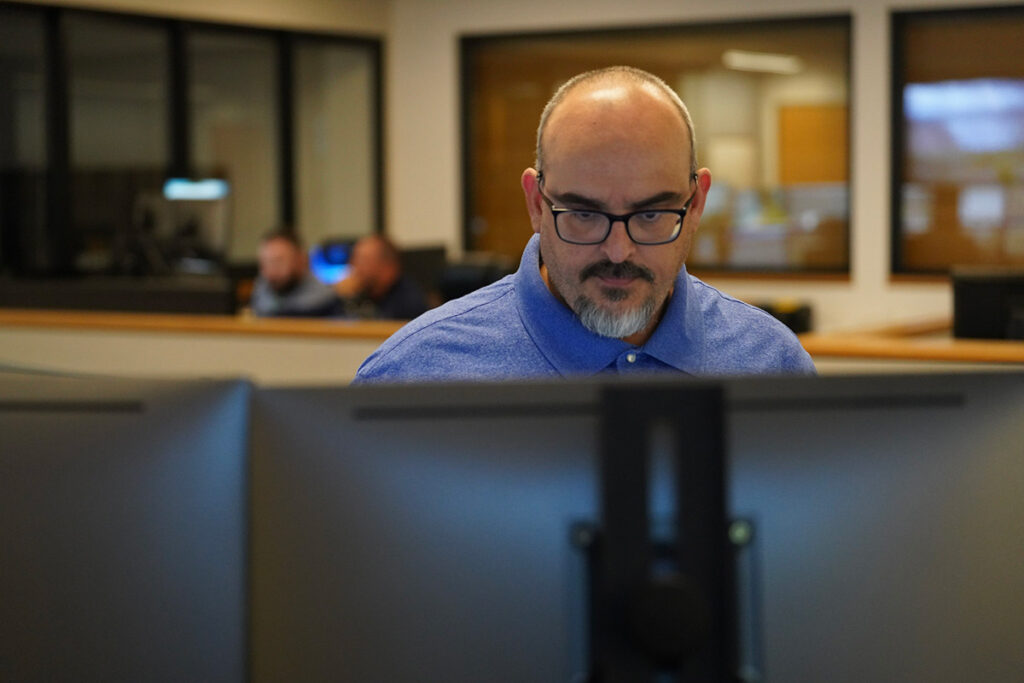

A team of 12, comprised of former military, municipal and industrial utility employees, takes water orders and cares for the valuable system infrastructure so that safe and reliable deliveries can benefit more than 6 million people.

“We can monitor and operate the system 24/7, 365 days a year,” CAP’s Water Control supervisor Andrew Tatlow said, “without physically being at each location.”

A remotely operated, water delivery wonder

Here is some of what the Control Center operates:

- Check gates. Think of these as miniature dams. As water is lifted uphill at each pumping plant before flowing by gravity to the next plant, 39 check structures raise and lower to control the flow of water. On a Control Central monitor, there is a graphic resembling a radial gate along with figures showing the gate’s position. Dispatchers can input a set point for how many feet they’d like to open or close the gate. Then with a click of the mouse, the gates on the system obey.

- Pumps. There are more than 109 individual pumps on the SCADA system that CAP operators can start and stop to meet diversions of Colorado River water from Lake Havasu and water user delivery needs.

- Maintenance and reliability. Control Center alarm points bring dispatchers’ attention to many possible issues, such as low oil pressure, malfunctioning fire alarms or a need to adjust a breaker or relay switch. CAP has an entire Centralized Maintenance and Reliability team dedicated to preventative maintenance and inspections.

- Water levels. Sensors from the system relay real-time data to Control Center dispatchers, including alerts about canal water levels being too high or low. “It should not get to the point where there’s an alarm,” Tatlow said. “CAP is constantly monitoring water levels and flows in order to correct a potential issue before there’s even an alarm notification.”

- Flood control. The CAP system is loaded with flood control features that manage storm water. In extreme cases, where a storm might threaten to spill Lake Pleasant water levels over the dam, Control Center operators can monitor and operate release valves and spillways to observe and control Lake Pleasant’s elevation in the event of flooding.

- Emergency response. Operators are capable of coordinating emergency response operations around the canal – even in remote locations.

The CAP Control Center team

Ayala and Tatlow are among approximately 12 dedicated employees within the Control Center.

About 50 percent of the employees are ex-military (such as Tatlow, who was enlisted in the Royal Navy, the naval warfare force of the United Kingdom, from 1999-2015); the others are generally comprised of either former employees of municipal water treatment and distribution departments (such as Ayala, a former wastewater public works employee with the City of Avondale) or heavy industrial utilities such as regional power plants and the Palo Verde Nuclear Generating Station.

The crew works around the clock alternating 12-hour shifts to provide continual monitoring and operation of the CAP system – days, nights, weekends and holidays. “That’s just something you accept,” Ayala said. “With your families, you might celebrate Christmas another time. And that’s OK.”

That’s because they proudly deliver water to Arizonans, all from one data-driven room, sending orders to the invisible hands in the desert.

KRA: Workforce

Being a premier employer that attracts and retains an exceptional and diverse workforce